The Million Hands project has just won two awards: (1) Million Hands: Prosthetic Hands for Children through an Open Source Platform, 3D Printers and Sensors and (2) Helping Hands – Playground Edition. All are based on BEST Labber graduate student Daniel Lim’s research.

Million Hands: Prosthetic Hands for Children through an Open Source Platform, 3D Printers and Sensors

This award is a CITRIS Seed Grant intended to support early-stage research that can be leveraged into significant external funding and maturation of the technology. The PIs are Grace O’Connell and Alice Agogino from UC Berkeley and Sanjay Joshi at UC Davis (all Mechanical Engineers). Our goal is to create functional prosthetic hands that can be fabricated at low-cost for the millions in need. We are focusing on children with low-level amputation or birth defects who are often disadvantaged due to the high cost of prosthetic hands that must be periodically replaced during periods of childhood growth.

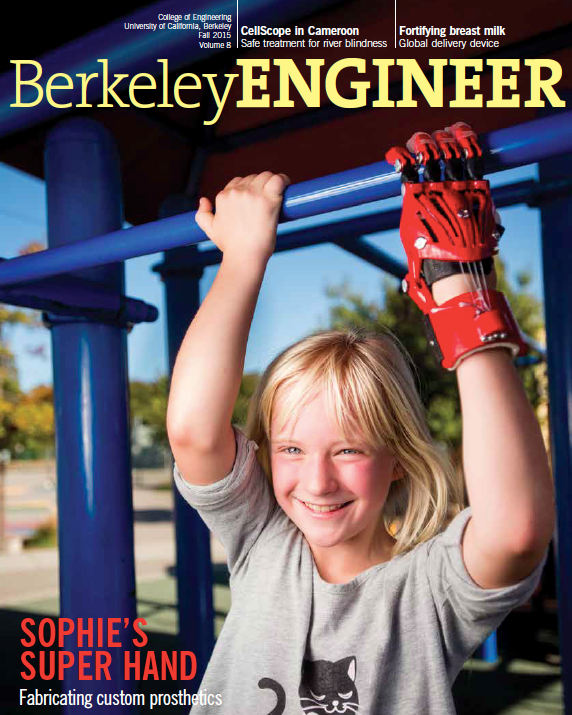

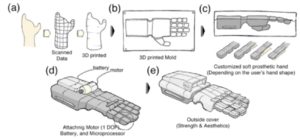

Even though 1.6 million people in the U.S. and countless more globally are in need of prosthetic devices, the current prosthetic hand market doesn’t serve the demand for children or those with low incomes due to pricing that can be well over $10,000 per hand. In this research, we will be developing a new design platform and fabrication method for prosthetic hands that can fit different shapes of hand deficiencies and scale as a child’s body grows. This research was first inspired from the maker movement’s ‘Enable community’ challenge to make prosthetic hands for children under $50 using 3D printing technology. Using equipment in the CITRIS Invention Lab, we were able to make prosthetic hands for an eight-year old child named Sophie (see Sophie’s super hand project covered in Berkeley Engineer Magazine). Through iterating on various improvements in a prosthetic hand for Sophie, we learned that the challenge for customized design of prosthetic hands is that it requires long hours of CAD modeling for each person and current platforms can’t handle different shapes of hands. In order to lower the design cost, we are developing a fabrication method that can significantly lower the design and fabrication costs of prosthetic hands using modular connected 3D printing, community/ crowdsourcing and open data product platform technologies. We have also started an initial network with Eric Dijkhuis (Po Paraguay), Kyujin Cho (Seoul National University) and a local maker of 3D printing systems.

Fabrication process of a prosthetic hand: (a) Scanned data from the user (b) 3D printed mold (c) Customized mold based on user’s finger shapes (Silicone casting) (d) Connecting tendons to the motor (Simple 1 DOF for grabbing) (e) Covering soft inner parts with 3D printed covers (ABS).

Evolution of 3-dimensional prototypes; from hand mold, brainstorming, low-fi prototype, consumer grade prototype to industrial grade prototype.

Helping Hands – Playground Edition

The award from the CITRIS Tech for Social Good program is to support students in early-stage technology research, hardware, software, web or mobile application development that address issues in Health, People & Robots, Connected Communities, Sustainable Infrastructures, and Diversity and Inclusion in Tech.

The goal in the Tech for Social Good project titled Helping Hands – Playground Edition is to develop a prosthetic hand strong enough to enable physical activities currently unsupported by other DIY prosthetic hands–like the use of monkey bars–for kids with upper limb deficiency. Our mission emerged out of an earlier project, “Sophie’s Super Hand,” that was featured as a cover story in Berkeley Engineer Magazine (Fall 2015) and on the main page of the “Tech for Social Good” program. For that project we used CAD software to modify Enable Community’s open-sourced prosthetic hand to create a form-fitting model for Sophie. See the full article and video: http://engineering.berkeley.edu/magazine/fall-2015/sophies-super-hand

The project was successful insofar as Sophie was able to own and use a prosthetic hand for the first time; however, the fitting and functionality of the design were limited, preventing her from using it in her daily life. Now we are collaborating with the chapter of Enable Hand in SF to develop a more functional prosthetic hand that kids can use in their daily lives. We have two need-knowers, Sophie and Lia, who have similar hand-shapes, and who have both had the same experience of trying to play with friends on Monkey Bars, only to find themselves with painful bruises on their wrists and otherwise unable to join in.

Our goal for this project is to build two prosthetic hands–one for each child–that enable them to play on their local playground’s Monkey Bars, and to document the design process to let other open-source communities use our method as a reference.

Sophie’s Super Hand

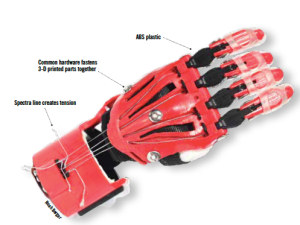

The Berkeley Prosthetics Project (BPP) is a volunteer team that designs prosthetics for people in need of a customized solution. Under the leadership of BEST Labber Daniel Lim (photo below left), the team uses the prototyping facilities of the CITRIS Invention lab, such as 3D printers, scanning devices, and laser cutters to build customized prosthetics. The team is currently designing a prosthetic hand (photo below right) for a young girl named Sophie.

Daniel Lim is a UX design freelancer in the Silicon Valley specialized in prototyping, industrial design and business modeling. He is also working with Alice Agogino and Euiyoung Kim to work on Internet of Things (IoT) research with Samsung Electronics and on building a tangible design roadmapping system. His MEng research was on the UX Design of a smart office. He was granted a Master’s degree from M.Eng (Master of Engineering) program at UC Berkeley in 2015 and currently working as a UX designer in the BEST Lab and Invention lab in UC Berkeley.

|

|

The project is also being displayed at the CITRIS Tech Museum. Molds of Sophie’s hand are shown in the white models in the upper left in the featured image below, along with some of the early prototypes for communicating and testing options. The parts are printed from ABS plastic at a cost of less than $10 to make.

News update: Daniel Lim, Hyunil (Chester) Cho and Brennan Chung won second place in a 3D printing Designathon with prompt: Come up with assistive technologies using 3D printing within 24 hours. They created a universal clamp that can fit into different sizes of prosthetic legs. Photo from the event below.

The story was also carried by Channel 5 6:00 pm CBS news on Wed., Nov. 28, 2015.

References

- “Sophie’s super hand”, Berkeley Engineer, Fall 2015: http://engineering.berkeley.edu/magazine/fall-2015/sophies-super-hand

- Ziegler-Graham K, MacKenzie EJ, Ephraim PL, Travison TG, Brookmeyer R. Estimating the prevalence of limb loss in the United States: 2005 to 2050. Arch Phys Med Rehabil. 2008, 89(3):422–29. [PMID:18295618]

- Biddiss, Elaine A., and Tom T. Chau. “Upper limb prosthesis use and abandonment: a survey of the last 25 years.” Prosthetics and orthotics international3 (2007): 236-257.

- Tavakoli, Mahdi, and Anibal T. De Almeida. “Adaptive under-actuated anthropomorphic hand: ISR-SoftHand.” Intelligent Robots and Systems (IROS 2014), 2014 IEEE/RSJ International Conference on. IEEE, 2014.

- Berkeley Expert Systems Technology Lab, Prof. Alice M. Agogino, http://best.berkeley.edu/

- RASCAL (Robotics, Autonomous Systems, and Controls) Lab, Prof. Sanjay Joshi, http://research.engineering.ucdavis.edu/rascal/

- Berkeley Biomechanics Laboratory, Prof. Grace O’Connell Lab, http://oconnell.berkeley.edu/what-we-do/research/

- Robotics@SNU, http://roboticslab.snu.ac.kr/m/html/sub02_02_04.php

- 3D Printed e-NABLE Hands Inspire Po Paraguay, http://3dprint.com/101243/e-nable-hands-po-paraguay/

- E-nabling, Enabling the Future: giving the world a helping hand, http://enablingthefuture.org/

- Camp Winning Hand, http://www.childrenshospitaloakland.org/main/departments-services/camp-winning-hands-161.aspx